Orange peel texture is a common term used in various industries, particularly in automotive, painting, and construction. It refers to a surface that has an uneven, dimpled appearance, resembling the skin of an orange. This texture can be found on painted walls, automotive finishes, and other coated surfaces. While it might not always be desirable, understanding its causes, prevention, and remedies can help in achieving smoother, more aesthetically pleasing finishes.

What is Orange Peel Texture?

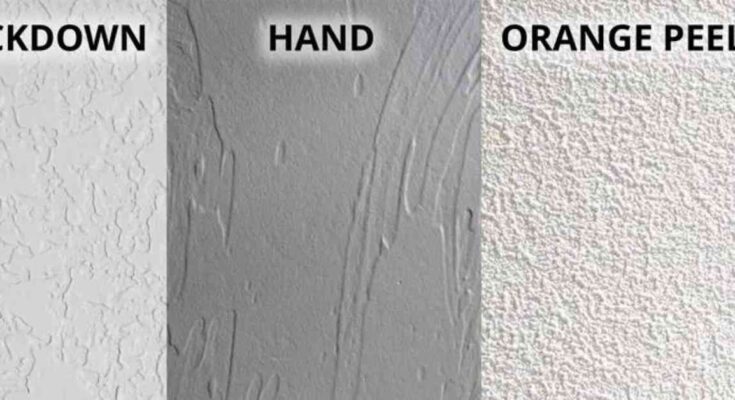

Orange peel texture describes a surface finish that has a bumpy, uneven appearance similar to the skin of an orange. It can occur in different contexts, including:

- Automotive Finishes: In the automotive industry, orange peel texture often appears in car paint jobs, leading to a less glossy and smooth finish.

- Wall Paint: In interior and exterior painting, walls can exhibit an orange peel texture if not properly applied or if the wrong materials are used.

- Furniture and Appliances: This texture can also be found on painted furniture and appliances, impacting the overall look and feel.

Causes of Orange Peel Texture

The occurrence of orange peel texture can be attributed to several factors, including application techniques, environmental conditions, and material properties. Here are some common causes:

1. Improper Application Techniques

- Spray Gun Settings: Incorrect settings on a spray gun, such as low air pressure or incorrect nozzle size, can lead to uneven paint application.

- Roller and Brush Marks: Using the wrong type of roller or brush, or not applying consistent pressure, can result in a textured finish.

2. Environmental Factors

- Temperature and Humidity: High temperatures can cause paint to dry too quickly, while high humidity can slow down the drying process, both contributing to an uneven surface.

- Dust and Contaminants: Dust, dirt, or other contaminants on the surface or in the air can interfere with paint application, leading to texture issues.

3. Material Properties

- Viscosity of Paint: Paint that is too thick or too thin can cause application problems. Thick paint may not level out properly, while thin paint can run and create uneven surfaces.

- Quality of Paint and Primer: Low-quality paint or primer may not adhere well to the surface, resulting in an orange peel texture.

Preventing Orange Peel Texture

Prevention of orange peel texture involves proper preparation, application techniques, and environmental control. Here are some tips to prevent this issue:

1. Surface Preparation

- Clean the Surface: Ensure the surface is free from dust, dirt, grease, and other contaminants. Use appropriate cleaning agents and techniques.

- Sanding: Sand the surface to create a smooth, even base. Use fine-grit sandpaper for the best results.

2. Proper Application Techniques

- Correct Equipment Settings: Adjust the spray gun settings according to the manufacturer’s recommendations. Use the appropriate nozzle size and air pressure.

- Consistent Application: Apply paint evenly using smooth, consistent strokes. Avoid overloading the brush or roller with paint.

3. Environmental Control

- Optimal Conditions: Paint in optimal temperature and humidity conditions. Avoid painting in extreme temperatures or high humidity.

- Ventilation: Ensure good ventilation to promote proper drying and curing of the paint.

Remedies for Orange Peel Texture

If orange peel texture occurs, there are several methods to remedy the issue and achieve a smoother finish:

1. Sanding and Polishing

- Wet Sanding: Use fine-grit sandpaper and water to sand the surface gently. This technique helps to level out the texture without damaging the paint.

- Polishing Compound: After sanding, use a polishing compound to restore the gloss and smoothness of the surface.

2. Repainting

- Priming: Apply a high-quality primer to create a smooth base. Ensure the primer is compatible with the paint.

- Multiple Coats: Apply multiple thin coats of paint instead of one thick coat. Allow each coat to dry properly before applying the next.

3. Professional Help

- Expert Services: In severe cases, seeking professional help may be necessary. Professionals have the experience and equipment to correct the texture and achieve a high-quality finish.

Orange Peel Texture in Different Industries

The impact and importance of addressing orange peel texture vary across different industries. Here’s how it affects some key sectors:

1. Automotive Industry

- Aesthetics: A smooth, glossy finish is crucial for the aesthetic appeal and market value of vehicles. Orange peel texture can detract from the overall look.

- Resale Value: Cars with a smooth, flawless finish generally have a higher resale value compared to those with visible texture issues.

2. Construction and Home Improvement

- Interior Walls: Orange peel texture on interior walls can affect the appearance of a room. Homeowners and decorators often prefer smooth finishes for a polished look.

- Exterior Surfaces: While some textured finishes are intentional for exterior surfaces, unwanted orange peel texture can still be a concern.

3. Furniture and Appliances

- Surface Quality: The finish quality of furniture and appliances impacts their attractiveness and perceived quality. Smooth finishes are often associated with higher quality.

Conclusion

Orange peel texture is a common issue that can affect various surfaces, from automotive finishes to painted walls and furniture. Understanding its causes, such as improper application techniques, environmental factors, and material properties, is crucial for prevention. By following proper surface preparation, application techniques, and environmental control, one can minimize the risk of orange peel texture. If it does occur, remedies such as sanding, polishing, and repainting can help achieve a smoother, more aesthetically pleasing finish.

In summary, addressing orange peel texture requires attention to detail, the right tools and materials, and an understanding of the conditions that contribute to its occurrence. By taking these factors into account, one can ensure high-quality finishes that enhance the appearance and value of the surface in question.